Executing a Quality Examination Using the AQL Method

The Acceptable Quality Limit (AQL) is a universally recognized procedure for quality control, employed by purchasers, providers, and third-party logistics companies to ascertain that products adhere to the mutually agreed quality standards.

Understanding AQL

The AQL procedure, as detailed by the International Organization for Standardization in ISO 2859-1, is a quality control method that allows you to assess the quality of an entire lot by examining a statistically significant subset of units randomly selected from the lot. The number of units chosen for the AQL process depends on the inspection level used and the total number of units in the lot. This guide will focus on AQL 2.5 Inspection Level S4, which is the standard level recommended by Lumi for all parties.

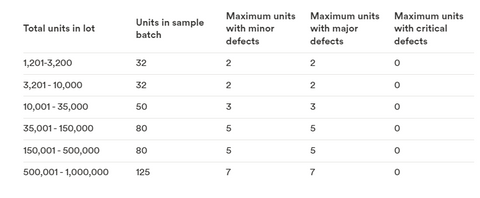

Step 1: Establish Your Sampling Plan

The first step is to decide the number of units that will comprise your sample batch. This number is dependent on the total number of units in the lot, which is usually the total units in a production run. After determining the number of units in your sample batch, record the maximum number of units with minor, major, and critical defects that are acceptable for the lot.

Step 2: Randomly Select Sample Units

To ensure a representative sample, randomly select units from the top, middle, and bottom of multiple pallets or bundles. Avoid choosing only from the top of pallets or bundles to get a true representation of the entire lot. An online number generator can assist in randomizing the selection process.

Step 3: Inspect Each Unit in the Sample Batch

Select your product from the list of Quality Policies to identify the appropriate inspection criteria. This criteria provides a standardized list of defects to watch for and specifies the allowed tolerances. Inspect each item in your sample batch and note the number and severity of any defects found. Photograph the defective units for review by the Lumi team and the supplier for root cause analysis.

Step 4: Determine the Number of Defective Units

If the number of units with minor, major, or critical defects is below the maximum acceptable for your lot, it passes inspection. However, if the number of defective units exceeds the maximum acceptable for your lot, report the issues promptly. Count the total number of defective units to expedite the process. Defective units are often found near each other within a production run.

Step 5: Report Any Quality Issues

Report any quality issues as they directly impact a supplier's scoring. To report a quality issue to the supplier, send an issue report with the order number, type of defect, defect severity, total number of units affected, photos of the defect, and proposed next steps for issue resolution.

Manufacturers often produce up to 10% more units than the ordered quantity to account for potential quality issues. Quality policies are enforced by the Order Terms, the agreement between you and your supplier. If a supplier consistently delivers poor quality or severe quality issues are reported, it will reflect in the supplier's scorecard and rankings on the platform. If quality issues persist, consider switching to a new supplier.

Leave a comment

Please note, comments must be approved before they are published